Prefabricated Capsule Rooms: A Practical Guide to Modular Micro-Living

Outline and How to Use This Guide

Before diving into materials and budgets, it helps to know where we’re going. This guide acts like a field manual you can skim for quick answers or read end to end for a complete plan. Whether you’re a homeowner sizing up a backyard studio, a hospitality operator testing a seasonal concept, or a campus planner evaluating dense housing, the structure below sets expectations and keeps decisions aligned. To keep examples concrete, we refer to Prefabricated Capsule Rooms as compact, factory-built modules designed for sleeping, study, or short-stay living. Think of them as building blocks that can be deployed singly or grouped, with services already integrated.

Here’s the roadmap we’ll follow and how each section helps you move from idea to action:

- Foundations and Form: What these units are, how they’re sized, what they’re made of, and how modules connect, stack, or expand over time.

- Budgets and Schedules: A grounded look at cost drivers, lead times, transportation, and on-site setup compared to conventional construction.

- Comfort and Longevity: How insulation, acoustics, ventilation, and moisture control affect daily life and long-term durability, plus sustainability levers.

- Use Cases and Decisions: Practical scenarios, a buying checklist, and maintenance routines so the investment stays safe, efficient, and compliant.

As you read, keep three principles in mind. First, context matters: climate, access roads, and permitting can shift your plan more than aesthetics. Second, systems thinking pays off: structure, services, and finishes behave as a single organism, so small choices have ripple effects. Third, reality checks beat wish lists: write down your constraints—budget, crane access, deadlines—so trade-offs are explicit. This approach turns a trend into a workable project and prevents surprises at delivery day.

What Prefab Capsules Are: Design Principles, Sizes, and Materials

At their core, Prefabricated Capsule Rooms are compact, self-contained modules manufactured off-site, transported on a flatbed, and placed on prepared foundations. Typical footprints range from about 2.4–3.2 meters wide and 3–6 meters long, sized to comply with road transport limits and to optimize factory workflows. Heights often allow a comfortable ceiling plus insulation and service cavities. The goal is to compress essential functions—sleeping, storage, lighting, ventilation—into a precise envelope that feels calm rather than cramped.

Common structural approaches include light-gauge steel frames, laminated timber, or composite shells. Each offers distinct trade-offs:

- Steel frames: slim profiles, predictable tolerances, and strong performance under transport loads; thermal breaks and careful detailing reduce cold-bridge issues.

- Engineered timber or cross-laminated panels: warm aesthetics, lower embodied carbon, excellent stiffness; requires vigilant moisture management.

- Composite shells: curved forms and high strength-to-weight; detailing for services and repairability needs upfront planning.

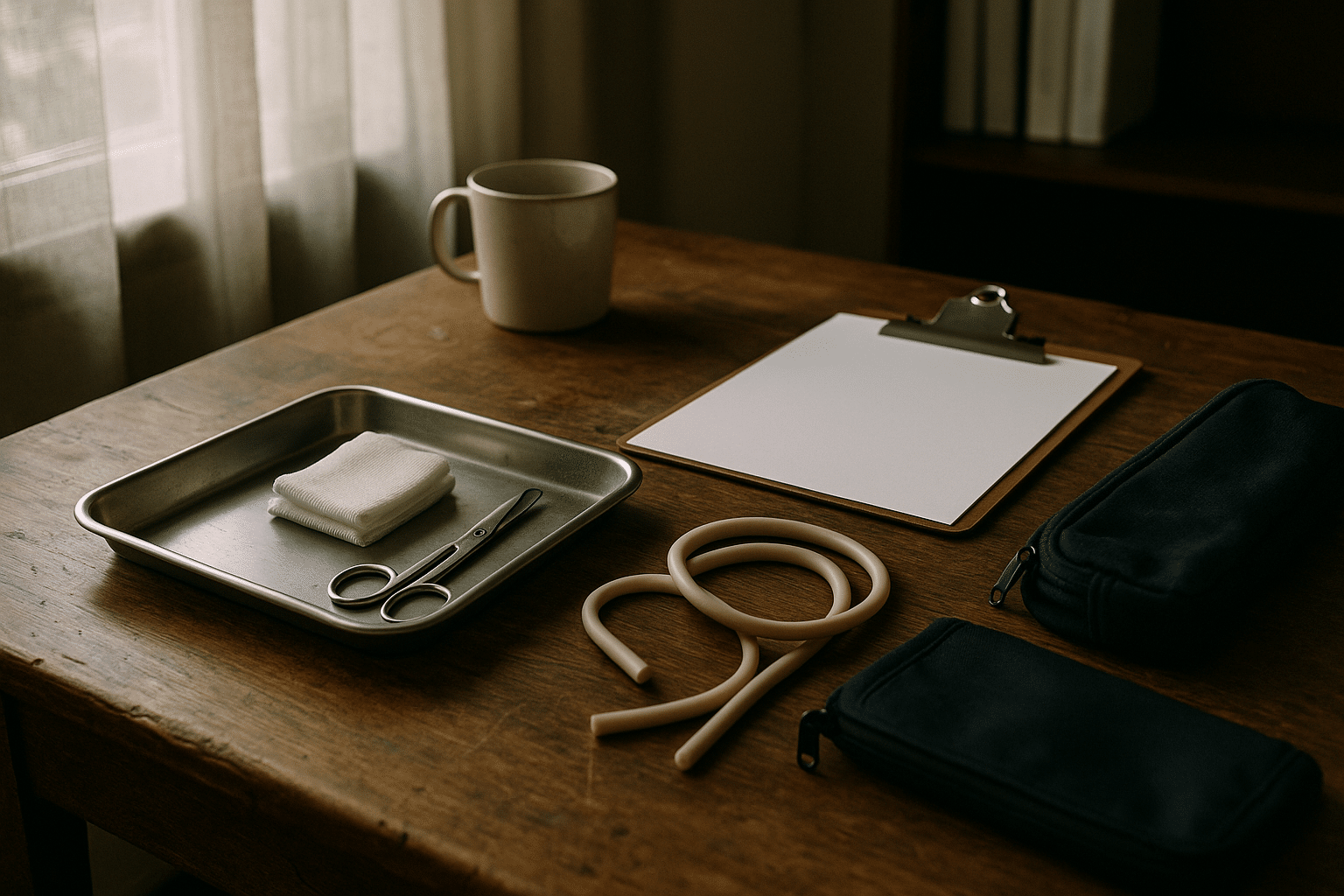

Inside, layouts borrow from yacht and rail design, using layered storage, pocket doors, and multi-use surfaces. Windows are placed for daylight without overheating, often paired with external shading. Interiors typically include:

- Integrated service wall with electrical distribution, outlets, and low-voltage controls.

- Insulated envelope targeting seasonal comfort; many aim for wall assemblies around R-15 to R-25 equivalent, depending on climate.

- Ventilation via continuous mechanical supply and extract, sometimes with heat recovery to tame humidity and odors.

Connection methods—corner posts, inter-module gaskets, or bolted plates—allow units to dock into small clusters, corridors, or stacked micro-hotels. The design intention is repeatable precision: the factory ships a consistent product that meets code, and the site team assembles quickly, limiting weather exposure and errors.

Costs, Schedules, and Logistics: How the Numbers and Moves Compare

Budgeting Prefabricated Capsule Rooms starts with a simple rule: separate the factory price from everything that happens on site. The ex-factory figure typically includes the structure, insulation, interior finishes, pre-wired electrics, and fixtures. What it does not include—foundations, cranage, delivery, hookups, permits, and local taxes—can add 20–45% depending on distance and site complexity. Treat the total cost of ownership across the first five to ten years, not just day-one purchase price.

For timelines, a typical sequence looks like this: design finalization (2–6 weeks), permitting (varies by jurisdiction), fabrication (4–12 weeks), delivery and set (1–3 days), and commissioning (2–10 days). Compared with conventional small builds, factory production can reduce overall project duration by roughly 20–40% because site work and manufacturing happen in parallel, and weather delays are minimized. That speed matters for seasonal businesses or student housing where missing an opening window can erase a year of revenue.

Logistics drive feasibility. Most modules are sized for standard road width; oversize loads raise costs and require escorts. Key planning steps include:

- Access survey: check turning radii, overhead lines, bridge limits, and soft ground risks.

- Foundation choice: screw piles or concrete piers for minimal soil disturbance; slabs where thermal mass or heavy loads are desired.

- Lift plan: verify crane reach, swing radius, and exclusion zones; pre-plan rigging points to protect finishes.

- Utilities: map shortest routes for water, power, and data; consider trenching before delivery.

When comparing to traditional builds, include site overheads. Lean site durations mean fewer security costs, less neighborhood disruption, and lower waste hauling. In many regions, off-site fabrication can cut material waste by 30–50% through precise cutting and batch procurement. These savings, plus predictable factory labor, support more reliable estimates—useful if you’re reporting to investors or administrators who prefer clear cash-flow timing.

Comfort, Durability, and Sustainability: Living Well in a Small Envelope

Small spaces live or die by comfort. In Prefabricated Capsule Rooms, performance hinges on thermal control, airflow, acoustics, and moisture. A well-detailed envelope with continuous insulation, taped air barriers, and decoupled interior linings keeps drafts out and limits condensation risk. In heating climates, aim for lower air-leakage rates and balanced ventilation; in cooling climates, prioritize solar control and vapor-smart layers. Pairing the envelope with efficient heat pumps, operable windows, and shading devices gives users fine-grained control without constant tinkering.

Acoustics matter more than many expect. A 5–10 dB reduction in external noise can feel transformative at bedtime. Techniques include staggered studs or resilient channels, dense mineral insulation in partitions, and careful sealing around outlets. Inside, soft finishes and acoustic panels help tame reverberation in small volumes. For lighting, daylight first: glazing placed to the side of beds, light-colored interiors, and exterior shades reduce glare and heat gain. Task lighting at low levels prevents a cave-like mood without wasting energy.

Durability is about resisting movement, moisture, and use. Transport introduces stress, so robust corners, protected edges, and flexible sealants pay dividends. Wet areas deserve sealed membranes, back-ventilated cladding, and accessible service panels for easy repairs. Maintenance planning is simple but vital:

- Quarterly checks: filters, weep holes, exterior seals, and roof drainage.

- Annual tasks: recalibrate ventilation, inspect fasteners and tie-downs, refresh exterior coatings as needed.

- After severe weather: check racking, window seals, and foundation level.

On sustainability, off-site manufacturing can trim embodied carbon through material efficiency and shorter waste streams. Operationally, high-performance envelopes and right-sized HVAC lower energy intensity. Add-ons like rooftop solar or battery storage should be evaluated case by case, considering shading, local tariffs, and structural capacity. Most importantly, build only what you need: small, well-used square meters beat unused space every time.

Use Cases, Buyer’s Checklist, and Conclusion

Because they are compact and repeatable, Prefabricated Capsule Rooms slot into diverse scenarios. Hospitality operators deploy them as seasonal clusters near trails or beaches, using quick installs to sync with local calendars. Schools and training centers add them as quiet study pods or short-stay units during busy terms. Homeowners test the waters with a single module for guests or remote work, reserving the option to add a second unit later. Municipalities sometimes pilot micro-shelter villages, prioritizing speed, dignity, and safety while long-term housing is built.

Before you commit, run a disciplined checklist:

- Site and access: confirm delivery route, ground bearing capacity, and utility proximity.

- Codes and permits: clarify classification (temporary vs. permanent), fire separation, egress, and accessibility obligations.

- Envelope and comfort: verify insulation specs, acoustic targets, ventilation strategy, and shading details for your climate.

- Services: ensure electrical load calculations, water/waste plans, and protected service runs with access panels.

- Commercial terms: understand warranties, lead times, payment milestones, and after-sales support for parts and repairs.

For maintenance, keep a simple log. Replace filters on schedule, clean exterior vents, and inspect seals at seasonal changes. Treat minor scuffs and scratches early to prevent moisture ingress. If units are relocated, recheck level and re-tension fasteners after settling. These small habits preserve comfort and value.

Conclusion: For readers weighing compact living or agile accommodation, modular capsules offer a pragmatic path from idea to keys-in-hand. The combination of factory precision, predictable scheduling, and incremental scalability makes them well-suited to tight sites and evolving needs. With clear goals, a realistic budget, and the checklist above, you can move from browsing concepts to placing a dependable, efficient unit that serves people well today and adapts tomorrow.