Exploring the Benefits and Applications of Polycarbonate Roofing

Polycarbonate Roofing 101: What It Is, Why It Matters, and How This Guide Is Structured

Before diving into specifications and techniques, here is a quick outline of what you will learn in this guide. This helps you skim to what you need and return later for the finer points when your project moves from idea to installation.

– A concise overview of polycarbonate as a roofing material and why it has become a go‑to for daylighting.

– A practical comparison of sheet types, profiles, and thicknesses for different applications.

– Performance metrics that actually matter: light transmission, insulation, impact, and fire behavior.

– Design and installation essentials that prevent leaks, warping, and premature wear.

– Costs, sustainability angles, real‑world use cases, and a grounded conclusion.

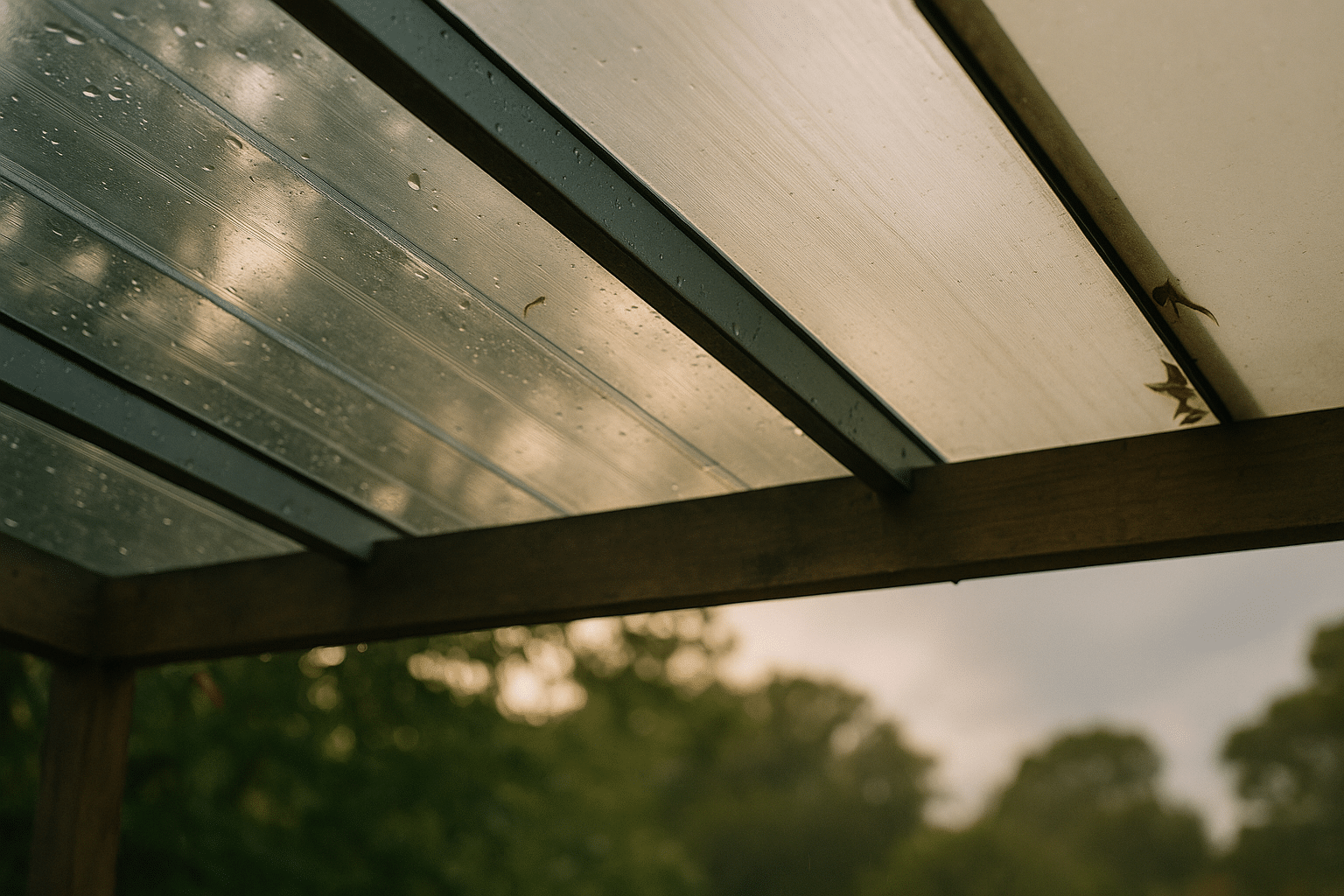

Polycarbonate is an engineering thermoplastic known for its high impact resistance, optical clarity in certain grades, and comparatively low weight. In roofing, those qualities translate to bright spaces that still feel protected—think covered patios that stay cheerful on gray days, greenhouse roofs that distribute light evenly, or industrial canopies that shrug off hail. Because the material weighs roughly half as much as glass by volume, it eases demands on framing and can reduce labor during installation. Sheets are manufactured in several forms, from glass‑like solid panels to fluted multiwall structures that trap air for insulation.

This matters for both function and comfort. Clear, diffuse, or tinted panels can balance solar gain and glare to suit climates and orientations, turning a hot mid‑afternoon into usable time instead of a retreat indoors. Co‑extruded UV layers resist yellowing and embrittlement, extending service life in sunny regions. Meanwhile, the chemistry of polycarbonate tolerates a wide temperature range—often cited from around −40°C to 120°C—so the same project can cope with frosty winters and searing summers without becoming brittle or sagging when properly supported.

As you read on, expect practical numbers rather than vague promises. You will find typical light transmission percentages, insulation figures for common thicknesses, and rules of thumb for spans, pitches, and fastener spacing. When building codes or manufacturer data could change the answer, we will point that out clearly. Think of this as a field guide you can keep open while sketching your frame, selecting a profile, or estimating costs for a bid.

Types, Profiles, and Specifications: Choosing the Right Sheet for the Job

Polycarbonate roofing is not one thing; it is a family of sheet constructions tailored to different needs. Selecting the format is the first big decision because it shapes how your roof manages light, heat, weight, and span. Four common options appear across residential, commercial, and agricultural projects: solid, corrugated, twinwall, and multiwall.

Solid sheets are the clearest and most glass‑like. In transparent grades they can transmit roughly 88–90% of visible light when new, depending on thickness and coatings. Typical thicknesses range from about 2–12 mm. Their rigidity and clarity suit canopies, protective overhangs, and areas where a sleek look is desired. Corrugated sheets trade a bit of optical perfection for stiffness through profile geometry. Thickness can be around 0.8–1.3 mm, but the waves add strength, allowing longer spans between purlins and quick installation with overlapping profiles that shed water effectively.

Twinwall and multiwall sheets introduce internal flutes or cells that trap air, improving insulation and cutting weight further. Common thicknesses include 6, 8, 10, 16, and 25 mm, with higher thicknesses generally delivering lower U‑values. For instance, a 10 mm twinwall might land around 3.0–3.2 W/m²·K, while a 16 mm multiwall can drop closer to 2.0–2.5 W/m²·K. Light transmission varies with color and wall count; clear 10–16 mm sheets commonly transmit in the 60–80% range, while opal or diffuse finishes trade some throughput for softer, more even light distribution—a desirable balance in greenhouses and sunrooms that need to limit hotspots.

Weight and handling are part of the appeal across all types. With a density near 1.2 g/cm³, polycarbonate sheets are significantly lighter than glass at about 2.5 g/cm³, letting you reduce structural mass or consider creative shapes. Many sheets can be cold‑curved within a specified radius, enabling arched canopies or skylights without heat forming. Adding tints—bronze, gray, or opal—helps tune thermal comfort by trimming solar heat gain or glare while preserving a pleasant brightness.

To narrow your choice quickly, use these prompts as a selection checklist:

– Need clarity and a sleek appearance? Consider solid sheets; size supports accordingly.

– Want longer spans and fast installation? Corrugated profiles make practical work of sheds, carports, and walkways.

– Trying to balance light and insulation? Multiwall sheets in 10–25 mm often provide a comfortable middle ground.

– Concerned about glare or heat? A diffuse or opal finish softens sunlight and can improve visual comfort.

– Planning a curve? Check the minimum cold bend radius; do not force a tighter arc than specified.

Performance and Durability: Light, Heat, Impact, and Fire

Performance decides whether a roof remains a joy or becomes a maintenance project. Polycarbonate’s headline trait is impact resistance. In standardized tests, it commonly outperforms annealed glass by a large margin—often cited on the order of hundreds of times greater impact strength—making it a practical option in hail‑prone regions or near ballfields. That resilience also helps when branches or wind‑blown debris test your canopy during a storm. For safety‑critical areas, always confirm local code requirements and use the specified thickness and fixing method.

Light transmission is the next lever. Clear solid sheets can deliver around 88–90% visible light transmission when new; multiwall sheets vary by thickness and color and typically land between 60–80% in clear grades. If you need gentle light that avoids glare on screens or plant leaves, consider a diffuse surface that spreads illumination more evenly. In greenhouses, diffusion can improve canopy penetration without sacrificing too much total light, creating steadier growth conditions across the bench.

Thermal performance depends on structure. For reference values, a typical 10 mm twinwall may post U‑values around 3.0–3.2 W/m²·K, a 16 mm multiwall around 2.0–2.5 W/m²·K, and a 25 mm sheet can nudge lower. These figures will not rival insulated metal panels or multi‑pane glazing with low‑E coatings, but for covered outdoor rooms and buffer spaces they often hit the comfort sweet spot. Temperature tolerance from roughly −40°C to 120°C helps the material remain stable in diverse climates, provided support spacing and expansion allowances are respected.

Fire behavior must be treated with nuance. Polycarbonate is a thermoplastic and will soften under high heat; flame spread and smoke development depend on sheet formulation and thickness. In some jurisdictions, certain sheets achieve favorable classifications such as B‑s1, d0 under EN 13501‑1 or comparable ratings in local standards, but certification varies by product and installation method. Always verify the stated classification for the exact sheet and thickness, and follow edge‑sealing and spacing rules that can influence performance.

Weathering resistance hinges on UV‑protective layers co‑extruded on the sheet surface. This barrier slows yellowing and retains impact strength over time, even in high‑sun environments. Routine cleaning with mild soap and water keeps dirt films from baking in and reduces the risk of abrasion during washing. Additional practical attributes include decent sound attenuation in thicker multiwall constructions and the ability to cold‑curve within published limits—a creative outlet for designers who want graceful arcs without added weight.

Key takeaways when evaluating performance:

– Impact: polycarbonate resists hail and debris far better than standard glass; thickness still matters.

– Light: clear for maximum transmission; diffuse for comfort; tints for solar control.

– Heat: multiwall improves insulation; match U‑values to climate and use.

– Fire: rely on verified classifications for the exact sheet; do not assume parity across formats.

– Weathering: a UV‑protected side should face the sun; maintain gently to extend service life.

Design and Installation Essentials: Framing, Slope, Expansion, and Maintenance

Thoughtful design prevents common failures like leaks, buckling, or cracked edges. Start with slope: a roof pitch of at least about 5° helps drainage and discourages standing water. Corrugated profiles are particularly forgiving at shedding rain when overlapped correctly; solid and multiwall sheets need attention to joint details and compatible glazing bars or caps. For snow country, calculate loads conservatively and consider steeper pitches or closer purlin spacing to limit deflection.

Thermal expansion is the silent force behind many complaints. Polycarbonate’s linear expansion coefficient is typically around 65–70 × 10⁻⁶ per °C. That means a 3,000 mm sheet can change length by roughly 6–7 mm across a 30°C swing. Plan oversized fastener holes, floating panel edges where permitted, and adequate perimeter clearances so sheets can “breathe” without buckling. Use fasteners with broad, UV‑stable washers, and avoid overtightening; the goal is secure yet flexible restraint, not a clamp that stamps rings into the sheet.

Support spacing depends on sheet type, thickness, and wind/snow loads. As a general orientation, corrugated sheets can span longer distances due to their profile stiffness, while multiwall and solid sheets may require closer supports to minimize deflection. Manufacturers publish span tables that account for regional loading; use them as your first stop, then verify against local codes. If you plan a curve, respect the minimum cold bend radius—often on the order of 100–175 times the sheet thickness for solid and multiwall formats. Tighter bends risk stress whitening or micro‑cracks that shorten life.

Edge and joint detailing for multiwall sheets calls for a few habits. Install the flutes vertically or in the direction of slope so condensation can drain. Cap the top with non‑vented aluminum tape to block debris; use vented tape at the downslope end to let moisture escape while filtering dust. Pair tapes with compatible U‑profiles to protect edges and improve appearance. For sealing, neutral‑cure silicones or EPDM gaskets are commonly compatible; avoid solvent‑based sealants and foams that can attack the plastic or leach plasticizers.

Cleaning and maintenance are straightforward. Rinse grit before wiping to prevent scratches; use mild soap, soft cloths, and plenty of water. Skip abrasive pads, strong alkalis, or aromatic solvents. Inspect fasteners, seals, and tape annually, ideally after winter and storm seasons. Remove leaves that trap moisture at laps, and check for algae along shaded edges where airflow is limited. Working at height remains risky—use fall protection and stable platforms rather than improvising from ladders and buckets.

Quick checklist for durable installs:

– Pitch at least about 5° for drainage; increase in snowy climates.

– Oversize holes for thermal movement; do not overtighten fasteners.

– Follow span tables for your specific sheet; adjust for local loads.

– Vent multiwall flutes at the eave; cap the top against debris.

– Clean gently and inspect seasonally to catch small issues early.

Costs, Sustainability, Real‑World Applications, and a Practical Conclusion

Budgeting for polycarbonate roofing involves more than the price per sheet. Lighter panels can reduce the size and number of rafters or purlins, and quicker handling lowers labor time. Multiwall sheets may cost more upfront than corrugated options but can repay the difference through comfort gains—less heat in summer, softer light year‑round, and potential reductions in artificial lighting. When comparing to glass, remember to factor the structural steel or heavy timber that glass often demands; a lighter envelope can shift the entire framing strategy.

Sustainability is a balance of inputs and savings. Polycarbonate is a durable plastic that can be recycled in many regions, though local streams vary. The biggest environmental win usually comes from daylighting: replacing daytime electric lighting and creating inviting spaces that get used instead of abandoned when the sun is harsh. Diffuse panels can improve daylight uniformity, reducing the need for blinds or supplemental fixtures. Long service life—often well over a decade with UV protection and proper detailing—spreads the embodied energy across many years of use. When end‑of‑life arrives, check local recyclers for clean polycarbonate acceptance and avoid contamination with sealants or tapes.

Use cases span everyday life and public spaces. Homeowners cover patios and pergolas to extend outdoor seasons without losing the sky. Gardeners and growers favor multiwall sheets for greenhouses that buffer cold nights. Schools and workplaces add walkways and bike shelters that feel safe and bright. Transit platforms, stadium concourses, and commercial entries benefit from impact resistance and quick shedding of rain. Even small touches—a porch awning, a side‑yard utility cover—can make a property feel more functional.

If you are weighing your next step, try this simple pathway:

– Define the experience you want: crystal‑clear views, soft daylight, or balanced privacy.

– Match the sheet type to that goal: solid for clarity, corrugated for fast builds, multiwall for comfort.

– Size the structure with verified span tables and local load data.

– Detail for movement, drainage, and clean edges; confirm sealant compatibility.

– Plan a seasonal maintenance check so minor issues never snowball.

Conclusion: For homeowners, contractors, and facility managers, polycarbonate roofing offers a practical way to welcome daylight without surrendering durability. Its mix of impact resistance, manageable weight, and flexible formats invites design creativity while staying grounded in constructability. With a sensible installation—right pitch, correct fixings, and room for expansion—you can count on bright, useful shelter that earns its keep through seasons of sun, rain, and the occasional hailstorm.